At Signature Audio, we’re constantly looking for ways to improve our services. Efficiency, quality, and consistency are the metrics we use to gauge how well the changes we make actually make a difference. By far, investing in advanced tooling has done wonders for our ability to provide high quality installations along with quick delivery times. In this article, we’re going to go over the advanced tooling at our shop and how each contributes to our business.

Our Stinger 3 by CAMaster has drastically improved our box building and custom design capabilities. With a 4’x8’ cutting area, we are able to cut large amounts of material both faster and more accurately than ever. This machine could have its own article on the number of applications it has become used for at our shop. Here’s a quick list:

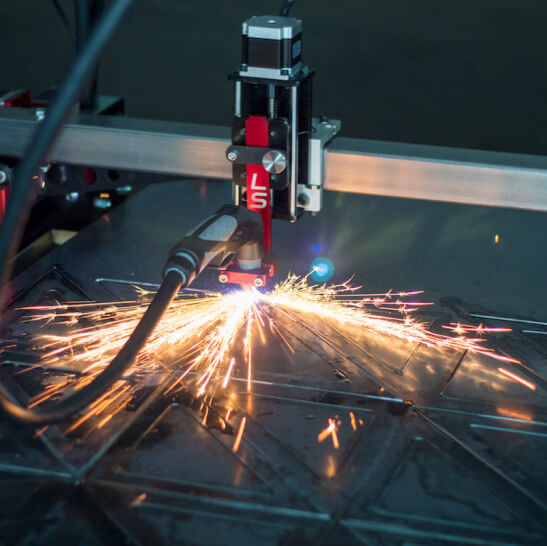

Our CrossFire Pro by Langmuir Systems has been a great addition to our metal fabrication capabilities. We’re constantly building brackets to secure equipment to vehicles for safety, durability, and serviceability. With the volume of brackets we build, being able to cut parts en-masse is a huge efficiency multiplier.

Our CO2 Laser by Universal was one of our first investments. Since then, it has been used weekly, if not nearly every day. We use it to cut and engrave all of our plastic materials. Similar to the CNC, the number of applications is tremendous. Here’s some examples:

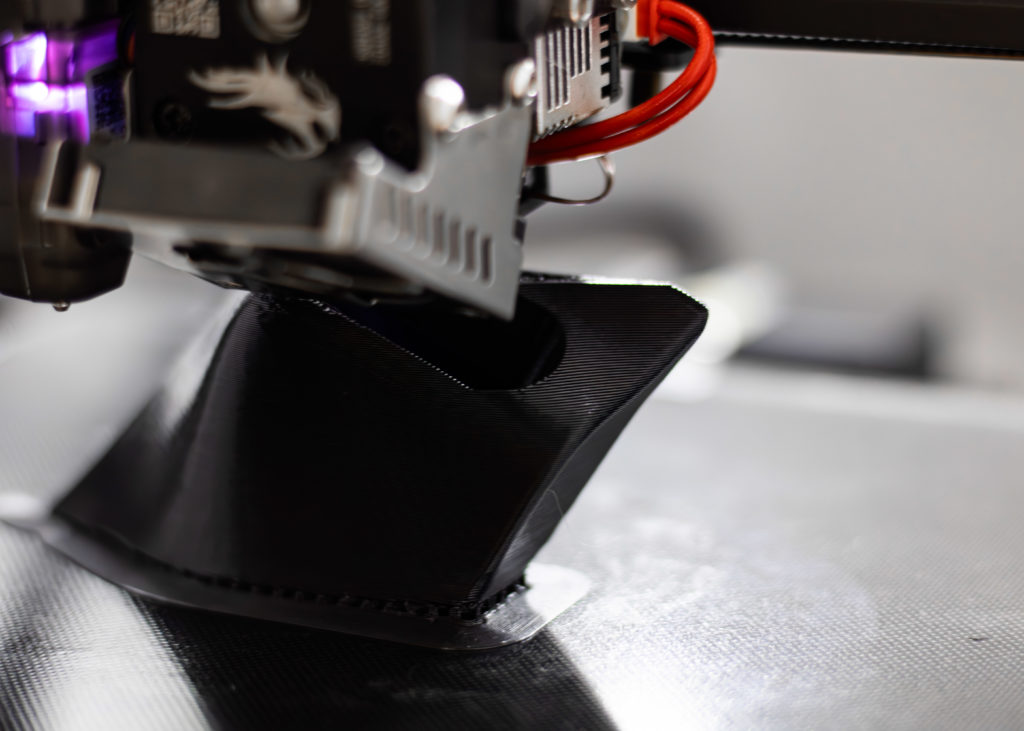

3D Printing technology has opened up a world of possibilities for our design capacity. We’re now able to take a digital design and turn it into reality with the click of a button. We are still exploring the applications, but so far, we use it for:

Using our Einstar by Einscan, we’re able to take digital scans of entire vehicle sections and design parts around or within those scans. This has allowed us to measure space restrictions, design full sub enclosures, and check fitment all before cutting a single piece of material. This is our newest investment, so we are still exploring applications. With what it has yielded so far, we’re excited to see what else we can utilize the technology for.

In conclusion, the integration of advanced tooling technologies at Signature Audio has been a game-changer in enhancing our service offerings. From the precision and efficiency of our 3-Axis CNC Router and CNC Plasma cutter to the versatility of our CO2 Laser and the innovation brought by 3D Printing and Scanning, each tool has uniquely contributed to our ability to deliver exceptional and customized audio solutions. These investments not only reflect our commitment to staying at the forefront of the industry but also our dedication to meeting and exceeding our clients’ expectations. As we continue to explore and embrace new technologies, we are excited about the future possibilities and the continued evolution of our services.

Address: 7432 E Tierra Buena Lane, Suite #101 Scottsdale, AZ 85260

Hours: Mon – Fri | 8:30am – 5:00pm

Phone: (480) 922-8180